About Dawnsun Kyosei Enginnering (DKEPL)

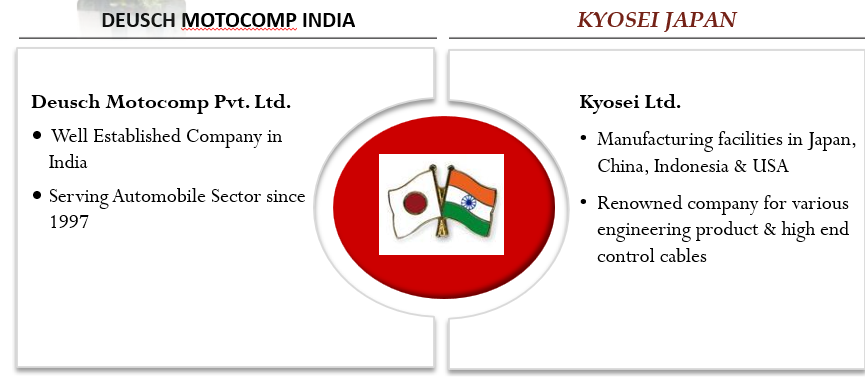

About Dawnsun Kyosei Engineering

Dawnsun Kyosei Engineering Pvt.Ltd.an Indo Japanese Joint Venture company is a high end new technology enterprise, integrated with superior technical design, worlds best practices in processing and manufacturing, to achieve utmost customer delight.

The Joint Venture enhances opportunities for customers to receive cost effective design & engineered appreciation from the very talented, experienced and client focused companies.

The plant is strategically located at the well-developed industrial area, having a favorable geographical and talent resources advantages.

The companies specialize in manufacturing of exhaustive range of Control Cables, by accumulated, rich experiences and technical resources. The corporation is fully prepared with its completely updated, leading technology, to face the challenges of worldwide market, sustaining competitive position, ahead of the markets.

The company focuses on high end new technologies as the key to have cutting edge quality, and aspire to be a world class leader in technology, service & concept.

JAPANESE TECHNOLOGY – INDIAN EXPERTISE

- World’s best machines, equipments and best practices are employed to ensure compliance to globally standardized manufacturing processes, meeting OEM standards and specifications.

- State of the art facilities and machines from Japan and the key processors are being replicated in India.

- Quality Assurance Systems are designed for POKA YOKE and various testing facilities ensure reliability and adequacy of our products.

- There product range consists of Push Pull Cable and Pull Cables including Clutch Lever, Throttle Lever etc.

Core Strengths of Dawnsun Kyosei Enginnering (DKEPL) Organization to Achieve Competitive Edge

- Contemporary & Advanced World Class Technology

- Japanese Management Practices

- State of the art manufacturing equipments from Japan

- Speedy New Product Development Capability

- Japanese manufacturing and quality control systems

- Technology and quality under direct supervision of experts from Kyosei,Japan

- Innovative Progressive Automation

- Utmost Energy Efficient Machines

About KYOSEI

Kyosei, Ltd was established in 1978 as a corporation which aim to produce and sell many types of control cables for agricultural machinery, automobiles, construction machinery and the like. KYOSEI has tried to progress to offer “High quality products of lowest price” and to deliver “Necessary amount at Necessary time to the Necessary Place” In order to achieve mutual advantage of customer, suppliers and us all, we continue making offort to enhance technology and to improve the credibility of quality.

Kyosei advanced to China in 1995, and to the US in 2004. They had expanded thier business field as often as the production and the sales base were secured in the world. Furthermore, the new head office and factory was completed in Japan in 2007. When this new base of latest equipment, technology and know-how is connected to our production and sales bases together, KYOSEI stepped forward to make a giant leap to the the brand-new “KYOSEI.”

Immediately after moved to a new office and factory, they vigorously started adoping the parts of ECO-vehicle; automobile parts, break cable, alminum die-cast prats, plastic molding parts and the like. Kyosei keeps promoting to advance and expand our business contents.

Product

Infrastructure

List of Machines

- AUTO OUTER CUTTING M/C

- ARC INNER CUTTING M/C

- AUTO INNER CUTTING M/C

- BUFFING MACHINE

- GRINDING MACHINE

- DEBURRING MACHINE

- DIE CASTING M/C

- HYDRAULIC PRESS

- CRANK PRESS

- INNER FLOWERING M/C

- PROOF LOAD TESTING M/C

- HOT STAMPING MACHINE

- TRAVEL LENGTH CUTTING M/C

- AUTO INNER INSERTION MACHINE

- TL CHECKING MACHINE & PROOF LOAD TESTING

- SLEEVE FIXING MACHINE

- SOLDERING MACHINE

- MANUAL INNER / SLEEVE CUTTING MACHINE

- MANUAL OUTER CUTTING MACHINE

- TAPE PASTING & SLEEVE ADHESION

- MANUAL ARC INNER CUTTING MACHINE

- PEELING/SKINING MACHINE

- HYDRAULIC PNEUMATIC PRESS

- HYDRAULIC PNEUMATIC PRESS

- HYDRAULIC PNEUMATIC PRESS

- HAND TRIMMING MACHINE

- SWAGING MACHINE

- CONVEYOR LINE (Single Pc FlowLine)

- ULTRASONIC WELDING MACHINE

- LINER FLARING MACHINE

- PROOF LOAD TESTING & TL CHECKING M/C

- MELTING MACHINE

Testing

All incoming raw materials and child part are received with a test certificate, analyzed & tested periodically to ensure quality and compliance with specification dimensionally before being used.

All House Testing Facilities

- Salt spray testing machine

- Profile Projector

- Universal Testing Machine

- Testing for Outer casing

- Stroke Load Efficiency Testing Machine

- Compression Test Machine for Outer

- Buckling Test Rig

- Torque Tester

- Fatigue / Performance Test

- Cable Efficiency test

- Dust Test Machine

- Push Pull Test Meter

- Universal Rig

- ORVM ENDURANCE TEST RIG

- Clutch Cable Endurance Test Rig

- Efficiency Testing Rig

- Travel Length checking & Proof Load testing 100 %

- Vibration

Plastic Parts Parameters

- Sp.gravity

- Material flow index

- Tensile strength

- Elongation

- Hardness (shore-D)

- Rheo Meter

- Ozone & Weatherability Testing

Rubber Parts Parameters

- Polymer test

- Hardness

- Tensile test

- Elongation test

- Compression test

- Heat ageing test

- Oil ageing test

- Ash content

Metal Parts Parameters

- Rusting (Salt Spray Test)

- Chemical composition

- Hardness Testing

- Plating Thickness

- Type of Plating(Trivalent &

- Hexavalent)

- Metallurgical & Chemical testing

Dynamic test Facility

- Endurance testing at specified Routing

- Hot & Cold (-40degree to +120degree)

- Dust Spray

- Vibration

- Operation Feeling Test

Static Test Facility

- No Load Sliding Resistance

- Flammability Test

- Mechanical Efficiency Test

- Load Testing

- Shower Test

- Rockwell Harness Test

- Torque Test

- Inner Cable Testing (Elongation, Breaking)

- Conduit Testing (Compression, Flexibility, Buckling, Bending)

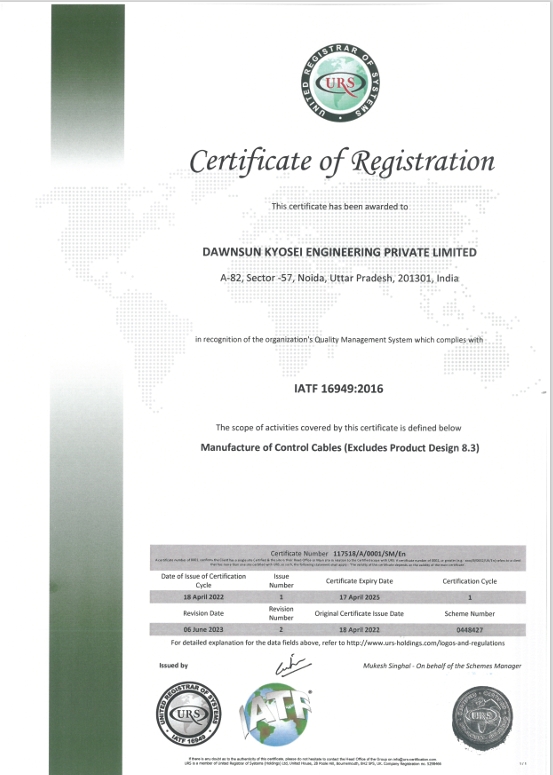

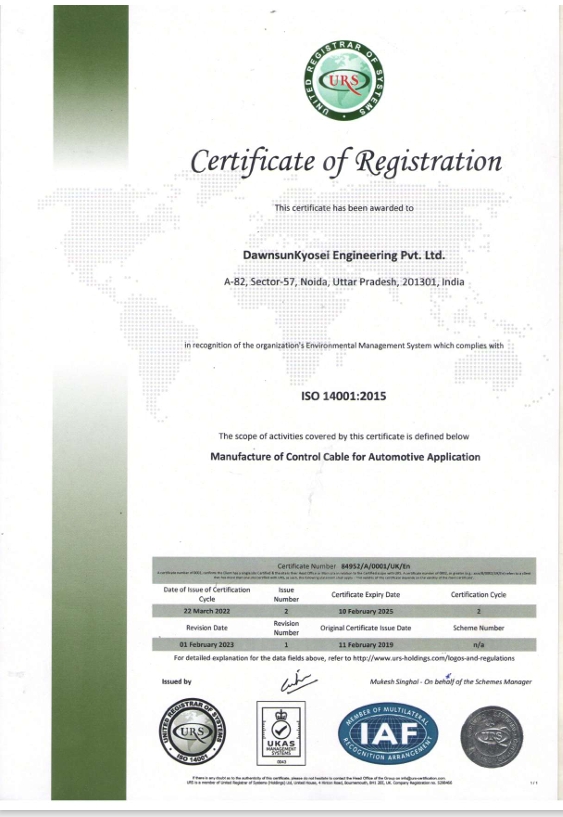

Certificates

ISO 45001:2018

IATF 16949:2016

ISO 9001:2015

ISO 14001:2015

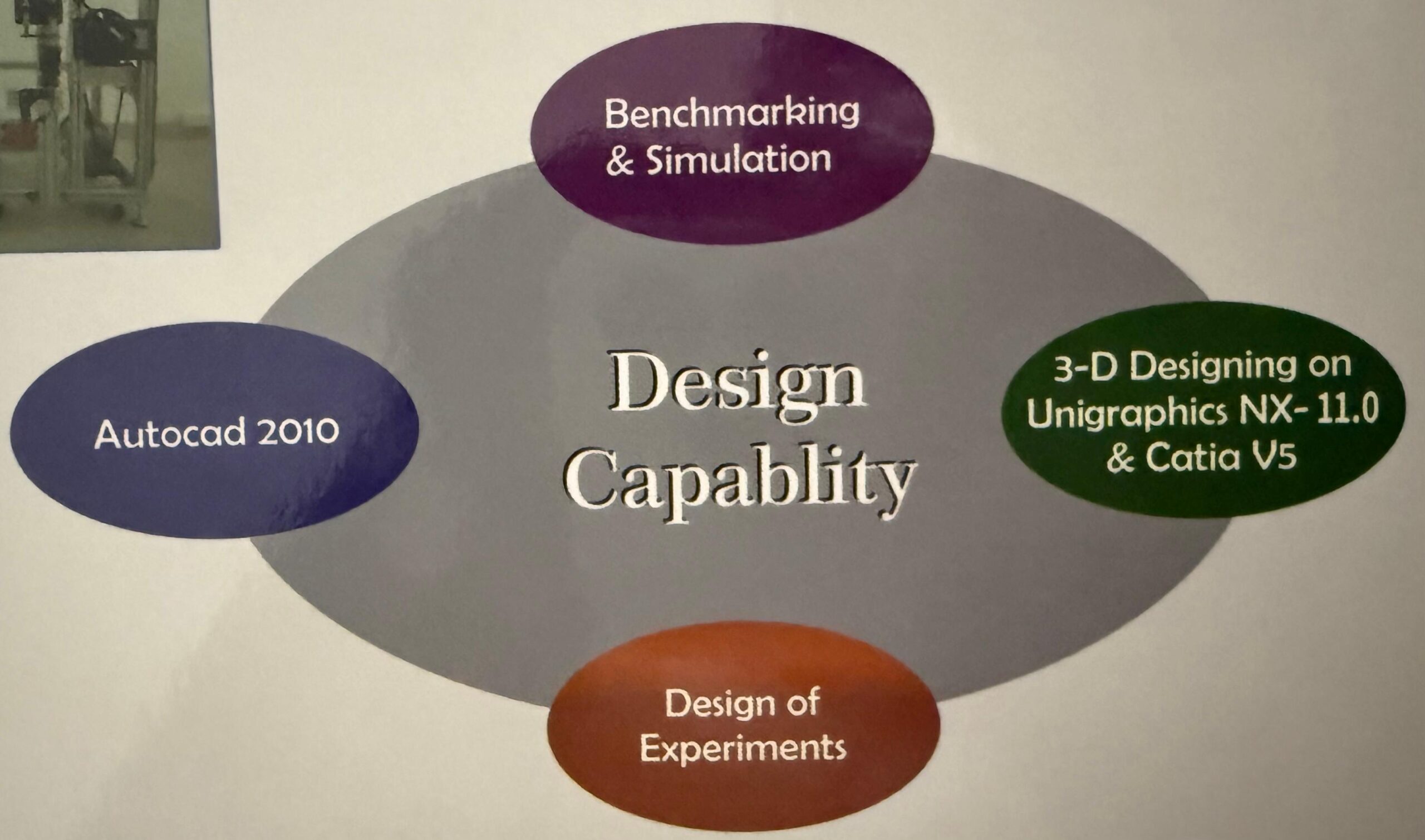

R&D

To develop complete Technical know-how of providing complete range of high performing automotive control cables with technical solutions with a view to applications requirement.

- Full design capability

- DOJO Training CENTER

- R&D Support from KYOSEI JAPAN

- IN-HOUSE DESIGN TEAM

- VARIOUS UNIQUE PROCESS & AUTOMATIONS TO REDUCE COST & INCREASE QUALITY CONSISTENCY.