About Deusch Motocomp SD(DMPL)

About Deusch Motocomp

Deusch Motocomp Pvt. Ltd. is a world class engineering company established in 1997 for producing wide range of rubber components for automotive OEMs and after market. DMPL, an ISO/TS 16949 certified company is a reputed supplier to OEM’s in the field of rubber moulded parts, rubber to metal bonded parts, rubber parts with plastic inserts etc.

Deusch motocomp’s Rubber Products, with SD Brand, connote quality, versatile new development capability, Quality consistency and high reliability. The young professionals have always aimed at total customer satisfaction. The company has young and dynamic team guided by highly experienced advisors from rubber industry to achieve standards in product quality and customer services.

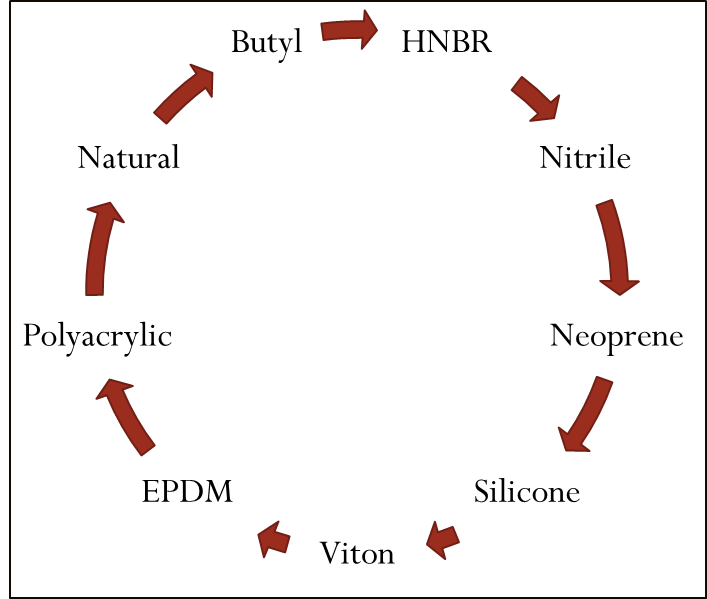

DMPL’s integrated services include Product development, development and manufacturing of tooling, Material and Rubber Compound development for oil, ozone, heat, high voltage, and high abrasion resistant parts from various specialty polymers viz. NR, SBR, NBR, EPDM, VITON, SILICON, POLYACRILIC RUBBER and HYDROGENATED RUBBERS

TOTAL SOLUTIONS FOR ECONOMIC PRODUCTION OF HIGH QUALITY POLYMER PARTS

Innovative compounding concepts where new ideas are implemented in hands on & process adapted way in plants mixing facility.

Product

Rubber Components for Two-Wheeler Motorcycle

Infrastructure

- World class engineering company established in 1997.

- Wide range of rubber moulded parts, rubber to metal bonded parts, rubber parts with plastic inserts etc.

- An IATF 16949: 2016 certified company.

- A reputed supplier to OEM’s and after markets.

- In house tool room and laboratory with R&D compounding capability.

- Advanced German Technology Machines

- Speedy product development

- Continuous growth with automations

Technology

- Advanced Technology Automated Machines

- Injection Moulding

- Compression Moulding

- Transfer Moulding

- High Quality optimized moulds maintained by processes of spark erosion ,wire cut , c&c milling &turning in a well equipped in-house tool room.

- Automatic weighing plant ensures Pokayoke from inception stage at chemical compounding level

- Carbon Storage in Cilos & Automatic Weighing

- Oil Automatic Storage, Weighing & Feeding

- Installation of automatic computerised chemical weighing plant for accuracy

POKA YOKE

- Automatic Carbon Weighing Plant

- Oil Weighing Equipment

- Innovative Automation at various operations with KAIZEN sensitive improvements

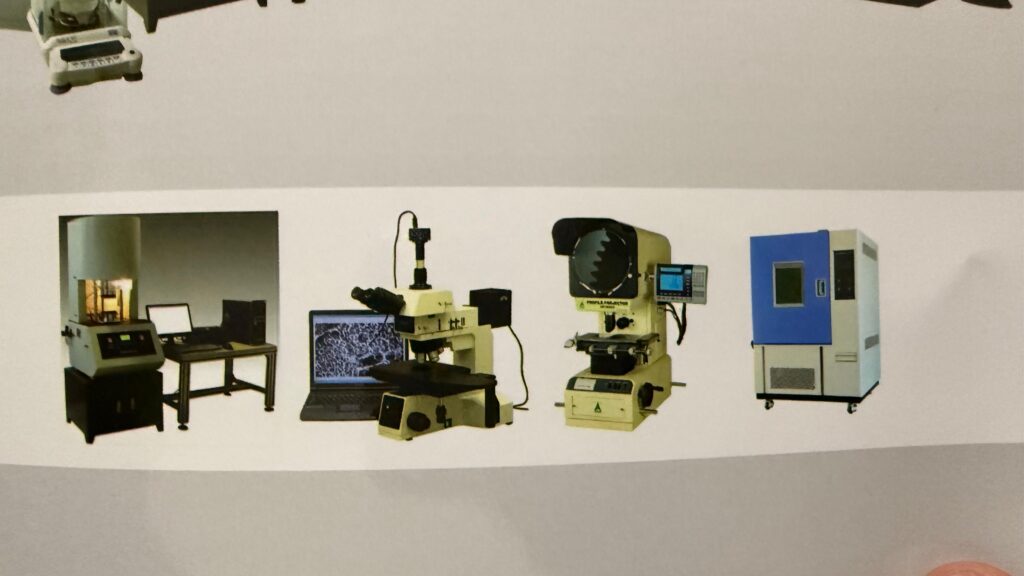

R&D and Testing

To develop complete Technical know-how of providing complete range of high performing automotive rubber parts with technical solutions with a view to applications requirement.

Well equipped laboratory to conduct different test needed for static and dynamic rubber parts, to achieve specific stringent properties required by Italian, Japanese & other international standards.

Well equipped laboratory

- Rheometer

- High Voltage Testing

- Water Leakage Testing

- Tensile Testing etc..

- Service & Practical training forms the basis of effective production

List Of Machine

- Hydraulic Machine

- Injection Moulding Machine

- Vacuum Compression Moulding Machine

- Mixing Mill

- Kneader

- Stitching Machine

- EDM Machine

- Lathe Machine

- Surface Grinder

- ARC Welding Machine

- Handdrill Machine

- Gas Cutter

- Hand Grinder

- Hydraulic Rubber Compression Machine

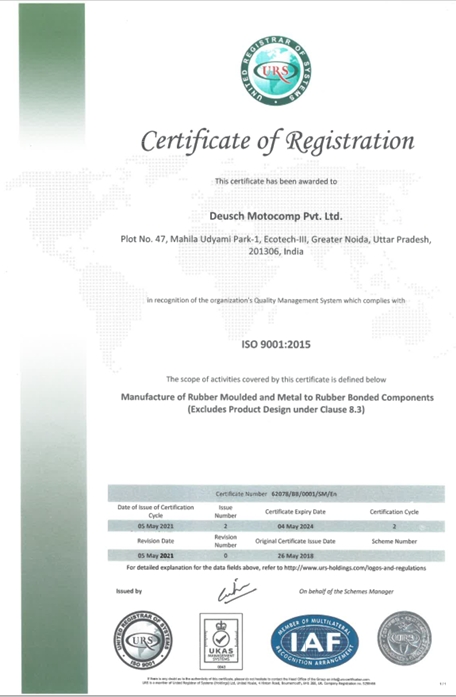

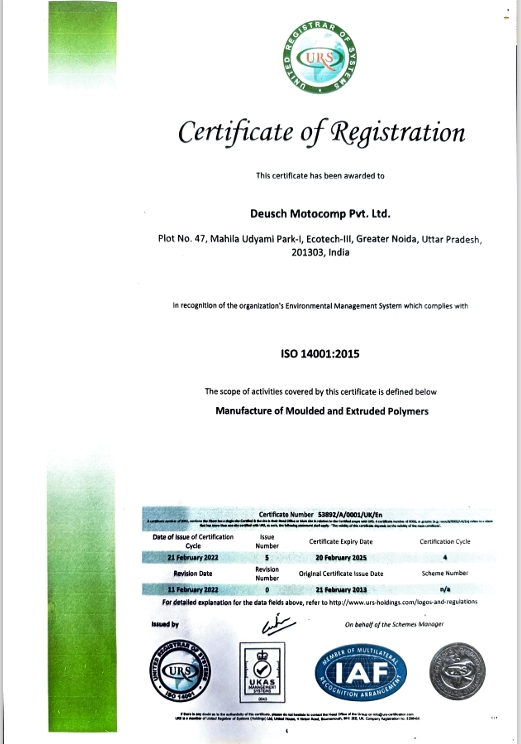

Certificates

ISO 14001:2015

IATF 16949:2016